STP Sludge Dewatering Machine Manufacturer

The constantly growing industrial landscape introduces a slew of new difficulties, one of the most critical being wastewater treatment. Sewage treatment facilities (STPs) are critical in this process because they ensure that clean water is returned to our rivers and streams. However, STPs produce a substantial amount of sludge, a semi-solid waste product that must be handled and disposed of properly. STP sludge dewatering equipment come into play here.

What is an STP Sludge Dewatering Machine?

Consider a machine capable of converting thick, sticky sludge into a dry, manageable cake. That is what a STP sludge dewatering machine essentially performs. These wastewater treatment essentials use a variety of methods to separate water from sludge, lowering its volume by up to 90%. This not only conserves landfill area but also reduces shipping and disposal expenses.

Types of STP Sludge Dewatering Machines:

There’s no one-size-fits-all solution when it comes to sludge dewatering. Different types of machines cater to specific sludge characteristics and treatment requirements. Here’s a brief overview of the most common types:

- Screw Press: These are the most widely used machines, utilizing a screw conveyor to press sludge against perforated screens, forcing water out. They are known for their reliability, high efficiency, and ease of operation.

- Belt Press: These machines employ an endless belt that filters sludge as it passes between rollers, squeezing out the water. They offer high capacity and are suitable for handling large volumes of sludge.

- Centrifuge: These high-speed machines separate solids and liquids using centrifugal force. They are ideal for dewatering oily sludge or sludge with high water content.

- Filter Press: These presses utilize a series of chambers and filter cloths to separate water from sludge. They are typically used for smaller volumes of sludge or when a very dry cake is required.

Choosing the Right STP Sludge Dewatering Machine:

Selecting the right machine for your STP depends on several factors, such as:

- Sludge type and volume: Different machines are better suited for specific sludge characteristics, such as its water content, solids concentration, and presence of oil or chemicals.

- Desired dryness level: The required dryness of the dewatered cake depends on disposal regulations and further treatment processes.

- Budget and operational costs: Different machines have varying initial costs, power consumption, and maintenance requirements.

- Space constraints: The size and footprint of the machine should fit within the available space at the STP.

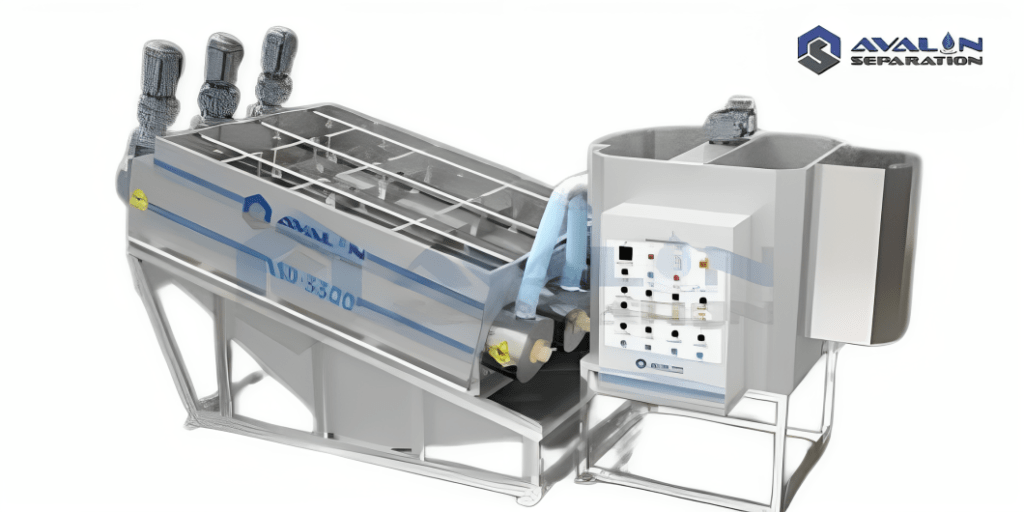

Why Avalon Separation Should Be Your STP Sludge Dewatering Machine Manufacturer:

Avalon Separation stands out as a leading manufacturer of STP sludge dewatering machines in India. With over a decade of experience and a commitment to innovation, Avalon offers a wide range of machines to cater to diverse needs:

- High-quality machines: Avalon machines are made of strong materials and undergo strict testing to ensure long-term performance and dependability.

- Product lineup diversification: Avalon has a machine for every sludge dewatering difficulty, from screw presses and belt presses to filter presses and centrifuges.

- Options for customization: Avalon realizes that no two STPs are the same. They provide tailored solutions to match unique needs and preferences.

- Avalon’s team: of skilled engineers offers complete assistance, from first consultation to installation and after-sales servicing.

- Avalon: delivers outstanding value for money, guaranteeing that you receive the highest performance without breaking the bank.

Investing in Avalon Separation means:

- Reduced sludge disposal costs: By significantly reducing sludge volume, Avalon machines help you save on transportation and disposal fees.

- Improved operational efficiency: Efficient dewatering processes ensure smooth STP operation and minimize downtime.

- Environmental sustainability: Avalon’s machines contribute to a cleaner environment by reducing landfill waste and minimizing water pollution.

- Peace of mind: With Avalon’s reliable machines and dedicated support, you can focus on what matters most – running your STP effectively.