Etp sludge dewatering machinery Manufacturer

Avalon Separation is the Best Quality of Etp sludge dewatering machinery Manufacturer in India, renowned for their dedication to quality, innovation, and sustainable solutions.

Effective waste management is essential in today’s environmentally concerned world. Etp sludge dewatering gear plays an essential role in this process for industrial and local institutions. This article looks into the topic of Etp sludge dewatering, examining its significance, various technologies, and essential factors for selecting the proper machinery for your needs. We’ll also introduce Avalon Separation, an established manufacturer of Etp sludge dewatering equipment, highlighting their experience and commitment to environmentally friendly solutions.

What is Etp Sludge Dewatering?

Effluent Treatment Plants, or Etps, treat wastewater created by various businesses. Sludge, a semi-solid residue, builds throughout this process. If not properly handled, this sludge might pose environmental and health risks. Etp sludge dewatering gear comes to the rescue by lowering the sludge’s water content, making it easier to handle, transport, and dispose of.

Why is Etp Sludge Dewatering Important?

Dewatering sludge has several advantages:

Reduced quantity: By eliminating water, the amount of sludge is reduced significantly, lowering storage and transportation expenses.

Simplified Disposal: Dewatered sludge is more controllable, making landfill disposal or burned easier.

Environmental Protection: Proper sludge management reduces soil and water body pollution, hence protecting the environment.

Resource Recovery: Dewatered sludge can be utilized for land application or production of biofuel in some situations, encouraging resource recovery.

Types of Etp Sludge Dewatering Machinery:

For Etp sludge dewatering, several methods are used, each with its own set of advantages and disadvantages. Here’s an overview of the most common:

Screw Press: To separate particles from liquids, this adaptable device includes a revolving screw conveyor. It is well-known for its durability, excellent efficiency, and capacity to handle a wide range of sludge kinds.

Filter Press: To dewater sludge, this process uses pressured filtration through filter cloths. It’s good for sludge with a high solids content, but it requires frequent maintenance and cloth replacement. Centrifuges: separate solids and liquids depending on density using high-speed spinning. They provide great dewatering efficiency but are costly and need professional operation.

Belt Filter: This method uses gravity and vacuum dewatering mechanisms to constantly transport sludge across a moving belt. It is appropriate for huge quantities of sludge but may not be useful for highly compressible sludge.

Choosing the Right Etp Sludge Dewatering Machinery:

Selecting the appropriate machinery depends on several factors, including:

- Sludge characteristics: Consider the volume, moisture content, and physical properties of your sludge.

- Dewatering requirements: Desired dryness level and processing capacity are crucial factors.

- Budget: Different technologies come with varying costs, both initial and operational.

- Space constraints: The available space at your facility dictates the size and footprint of the machinery.

- Environmental regulations: Ensure the chosen technology complies with local environmental regulations.

Avalon Separation: Best Quality Etp sludge dewatering machinery Manufacturer

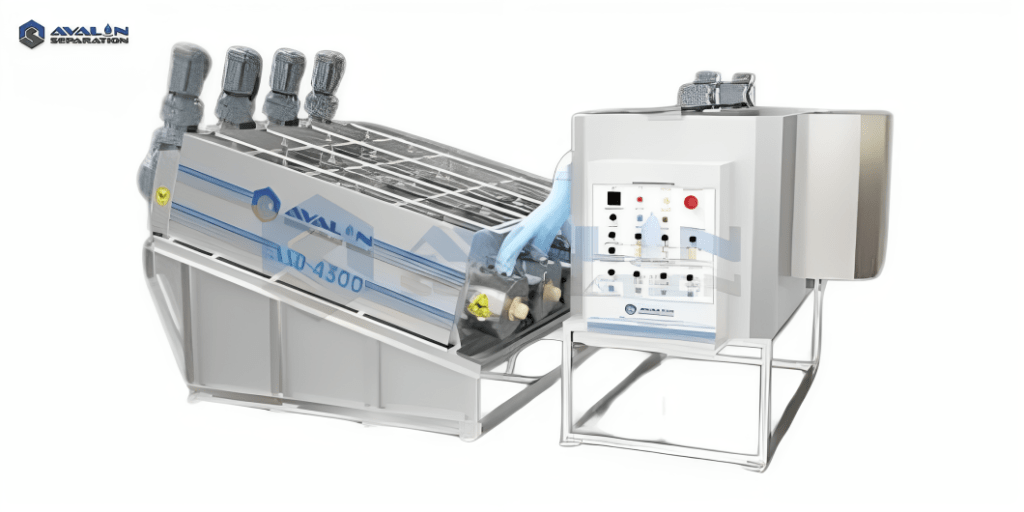

Avalon Separation is a leading manufacturer of Etp sludge dewatering machinery in India, renowned for their dedication to quality, innovation, and sustainable solutions. They offer a wide range of equipment, including:

- Screw Press Dewatering Machines: Available in a variety of sizes and designs to meet varied sludge kinds and dewatering needs.

- Filter Presses: Strong and dependable filter presses for effective dewatering of high solids sludge.

- High-performance pumps: provide improved dewatering results, perfect for difficult sludge applications.

- Sludge Dewatering Systems: Fully customized sludge dewatering systems that include conditioning, thickening, and dewatering units.

Avalon Separation’s dedication to quality extends beyond their goods. They offer broad after-sales services such as installation, commissioning, and continuous maintenance. Their skilled engineering staff also supports you in selecting the best machinery for your unique needs, assuring long-term efficiency and cost-effectiveness.

Investing in Effective Etp Sludge Dewatering

You can get significant environmental and economic benefits by selecting the correct Etp sludge dewatering technology and cooperating with a reputable manufacturer like Avalon Separation. You will not only contribute to a cleaner environment, but you will also optimize your waste management procedures, cut expenses, and maintain regulatory compliance.

Conclusion

Etp sludge dewatering is essential for appropriate waste management. Understanding the various technologies, selecting the appropriate apparatus, and collaborating with a certified manufacturer, such as Avalon Separation, enables you to treat sludge effectively and sustainably. We can all contribute to a cleaner and healthier environment by focusing on appropriate sludge dewatering.

- Manufacturer of Etp sludge dewatering machinery

- Etp sludge dewatering equipment supplier

- Top Etp sludge dewatering machine manufacturer

- Etp sludge treatment machinery producer

- Leading manufacturer for Etp sludge dewatering systems

- Etp sludge dewaterer machine maker

- Etp sludge decanter equipment supplier

- Reliable Etp sludge dewatering machinery manufacturer

- Etp wastewater sludge dewatering machine producer

- Etp sludge management equipment manufacturer

- Industrial sludge dewatering machinery

- Effluent treatment plant sludge dewatering

- Sludge dewatering process

- Municipal sludge dewatering equipment

- Belt filter presses for sludge dewatering

- Screw press dewatering systems

- Sludge thickening and dewatering

- Dewatering equipment manufacturer

- Sludge dehydrator machine

- Sludge drying equipment