Avalon Separation, established in 2015, is a rapidly expanding company specializing in the separation of solid and liquid components from industrial and city wastewater. We partner with a diverse range of sectors including municipalities, food and beverage, power and energy, slaughter and livestock, chemicals, pharmaceuticals, biogas, dairy, and oil & gas industries, and we have all kind of solutions related to What is Dewatering System ? & their types

Dewatering System

Dewatering systems are an essential part of many industrial processes, removing water from solids and sludges. They are used in a wide range of applications, including mining, construction, wastewater treatment, and manufacturing.

What is a Dewatering System?

Avalon Separation is the Manufacturer of dewatering system & a series of equipment that removes water from solids and sludges. The process typically involves several steps, including:

- Flocculation: Chemicals are added to the solids or sludge to cause the particles to clump together.

- Sedimentation: The clumps of particles settle to the bottom of a tank.

- Filtration: The solids and sludge are passed through a filter to remove the remaining water.

- Drying: The solids and sludge are dried to remove any remaining moisture.

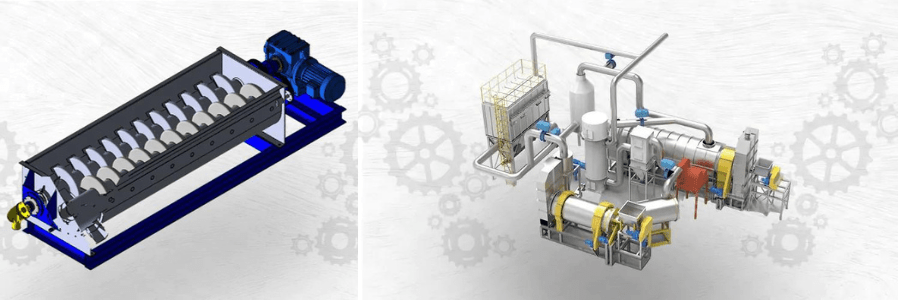

Types of Dewatering Systems

Welcome to Avalon Separation, your premier destination for cutting-edge wastewater solutions. As the leading Industrial Dewatering Plant supplier in Gujarat, we take pride in revolutionizing the way industries and municipalities manage their wastewater. Our state-of-the-art dewatering machines are meticulously crafted to efficiently separate solid and liquid components, ensuring environmental sustainability and regulatory compliance. With a commitment to excellence, Avalon Separation stands out as the best choice for businesses seeking top-tier dewatering solutions in Gujarat. Explore our range of innovative products and experience firsthand why we are recognized as the Best Industrial Dewatering Plant supplier in Gujarat.

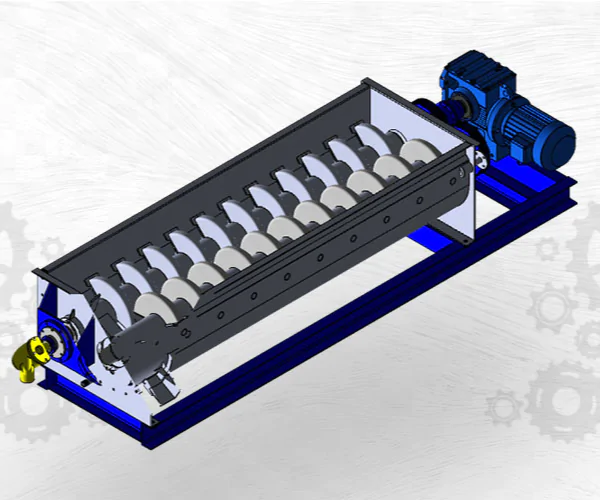

Screw Dehydrator

The Screw Dehydrator is an advanced sludge dewatering system. It’s clog-free, reducing the need for sedimentation and thickening tanks, saving on construction costs. Controlled by PLC, it’s a modern alternative to traditional filter presses. With low power and water consumption, it’s a cutting-edge solution compared to centrifuges. The Sludge Dewatering Press uses a central screw auger and multi-disk filter for efficient dewatering, producing a dry sludge cake. It’s cost-effective in terms of electrical, water, and polymer usage, with high capture rates. This system comes fully equipped and mounted on a stainless steel skid, including pumps, dosing system, and control panel. It’s easy to operate with automated startup and shutdown, requiring minimal operator intervention. In contrast, traditional methods like screw presses, centrifuges, and belt presses demand continuous attention, high energy, and extensive maintenance.

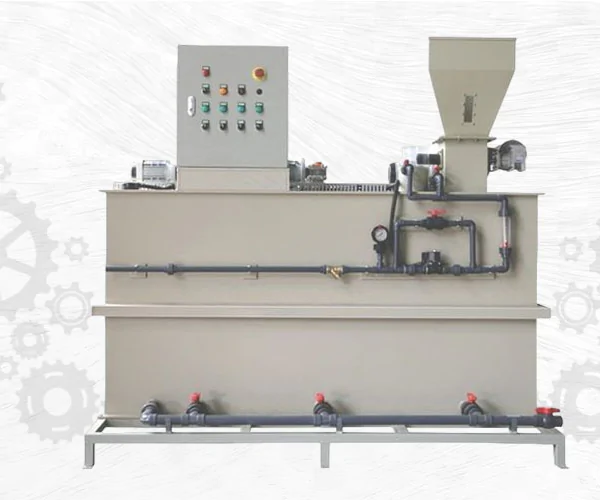

Auto Poly Dosing System

Auto Poly Dosing System is made up of a rectangular tank divided into three parts. The first section handles dilution and is equipped with a container for adding polyelectrolyte, a small screw device with adjustable speed, and a fast mixer for blending. It also has a system for adding water, a valve, flow meter, and pressure relief. The second part focuses on mixing and homogenization of the polyelectrolyte solution, using a slow mixer and a drainage system. The third section is for storage, equipped with a slow mixer and a delivery system for the polyelectrolyte solution. Each mixer has two impellers with four angled blades. The system automatically prepares the polyelectrolyte solution when the desired concentration (between 0.05% to 0.5% by weight) is set. The resulting mixture can be further diluted if needed.

Sludge Dryers

Sludge Dryer is designed for drying municipal sludge, which can then be used in various ways like agriculture, as fuel, or for incineration, reducing the need for landfill sites. This special equipment is adept at handling sludge with high moisture, viscosity, water retention, and low heat value. It can dry sludge with about 80% water content in one go. The dryer’s internal structure has been specially designed to enhance thermal efficiency and prevent sludge from sticking and over-drying. The sludge dryer comprises components like an induced draft fan, a dispersing device, a belt feeder, a rotary drum, a heat source, and more. Its working area includes a discharge section, an inclined lifting plate area, a cleaning zone, and a material guide area. This efficient system enables effective sludge treatment and resource utilization.

Paddle Dryers

Paddle Dryer is a type of indirect heating device. It’s ideal for handling materials like paste, powder, and granules that have good thermal stability. With special configurations, it can also handle heat-sensitive materials, substances that require solvent recovery during drying, and those that need to be dried under rough vacuum conditions. This versatile dryer can be used not only for drying but also for cooling powders and granules, as well as for crystallizing certain special materials by introducing a cooling medium. Additionally, it can inject a heating medium to warm up both the materials and the reactor being used. This makes it a highly adaptable tool for various drying and processing needs.

Applications of Dewatering System

Dewatering systems are used in a wide range of applications, including:

- Mining: Dewatering systems are used to remove water from tailings, which are the waste products of mining operations.

- Construction: Dewatering systems are used to remove water from construction sites, which can prevent soil erosion and flooding.

- Wastewater treatment: Dewatering systems are used to remove water from wastewater, which can improve the quality of the water before it is discharged into the environment.

- Manufacturing: Dewatering systems are used to remove water from manufacturing processes, which can improve the quality of the products and reduce the risk of environmental contamination.

Benefits of Dewatering Systems

Dewatering systems offer a number of benefits, including:

- Reduced waste disposal costs: Dewatering systems can reduce the amount of waste that needs to be disposed of, which can save money.

- Improved product quality: Dewatering systems can improve the quality of products by removing water that can cause contamination.

- Reduced environmental impact: Dewatering systems can reduce the environmental impact of industrial processes by preventing water pollution.

Avalon Separation: A Leading Provider of Dewatering Systems

Avalon Separation is a leading provider of dewatering systems for a wide range of applications. The company offers a variety of products, including centrifuges, filters, presses, and evaporators. AvalonSeparation’s products are known for their high quality and reliability.

How to Choose a Dewatering System

The best way to choose a dewatering system is to consult with an expert. AvalonSeparation’s engineers can help you to choose the right system for your specific needs.

Conclusion

Dewatering systems are an essential part of many industrial processes. AvalonSeparation is a leading provider of dewatering systems that can help you to improve your operations and reduce your environmental impact.

Call to Action

Contact AvalonSeparation today to learn more about their dewatering systems.

Additional Keywords

- Sludge dewatering

- Solid-liquid separation

- Water treatment

- Industrial wastewater treatment

- Mining dewatering

- Construction dewatering

- Manufacturing dewatering